|

|

Post by snyper on Aug 26, 2009 5:40:58 GMT 8

Here's a record of the progress we have compiled in the course of making our custom made PCP.

The design intent was to create a PCP for bench rest shooting that will have a low working pressure, less maintenance, and at least have an output of around 900 FPS. The inspiration for this endeavor is the USFT rifle. We are making 3 units as part of our prototyping process each with a slightly different modification.

|

|

|

|

Post by snyper on Aug 26, 2009 5:58:33 GMT 8

APRIL 13, 2009 After months of persuading our retired (from making airguns) airgunsmith we have finally coaxed him to build our PCP rifles. With enough research and inputs gathered and after several months on the round table during coffee sessions. We finally decided on the design and materials to use. Barrels. . .   Tubes & Pipes . . .   And more tubes and pipes. . .  Offsets and end plugs. . .    Rough Cuts. . .   Offset taking shape. . .  A borrowed piece, courtesy of a friend across the miles. . .  Finally slowly coming to a reality. . .

|

|

|

|

Post by snyper on Aug 26, 2009 5:59:32 GMT 8

|

|

|

|

Post by snyper on Aug 26, 2009 6:01:07 GMT 8

MAY 5, 2009Additional progress: Barrel being prepped for sleeving, receiver bored and shaped.  Another angle  closer view  A closer look at the receiver/breech parts.

|

|

|

|

Post by snyper on Aug 26, 2009 6:01:26 GMT 8

|

|

|

|

Post by snyper on Aug 26, 2009 6:51:13 GMT 8

|

|

|

|

Post by snyper on Aug 26, 2009 6:51:59 GMT 8

June 14, 2009More pic updates: Setting the screws on the plugs and offset in place  Closeup of the receiver   Here's a close up of the other end  Pressure Guage installed(?),hehehe mock up lang.

|

|

|

|

Post by snyper on Aug 26, 2009 6:52:22 GMT 8

June 17, 2009UPDATE: TEST FIRING Finally we are able to complete the action and it is now ready to be filled with air. For its test fill we used CO2, No leaks! Valve system works. Goal for today is to see if the whole assembly will hold air, and see if it shoots right. And it does! Here our gunsmith, manong pepe is testing the first shot on the chrono just to get an idea, note that there is still no stock just the whole action.  Another Angle  First shot, darn! I pressed the camera too soon this should have read 692 fps. The fill is from a used pygmy tank though and the hammer spring is from a scrap armscor spring lying around hehehe. These are just test shots and tuning has not been done yet.  Another test shot, I was not able to take the pic properly.   Third shot  Raymond looking at the action notice the free floated barrel, with him is our ever reliable gunsmith, manong Pepe.  A closer view of the barrel and reservior.  Here are some close up pics, screws have been replaced with the final allen head bolts. This is the muzzle end and fill port. Note that the plug has been "blued" hehehe.  Another angle.  Closer look.  A closer pic of the offset, barrel, receiver.  Another angle.  The trigger with its temporary trigger post.  The mock stock, use your imagination hehehe. . .  Estimated overall length 44inches

|

|

|

|

Post by snyper on Aug 26, 2009 6:53:40 GMT 8

|

|

|

|

Post by snyper on Aug 26, 2009 6:54:02 GMT 8

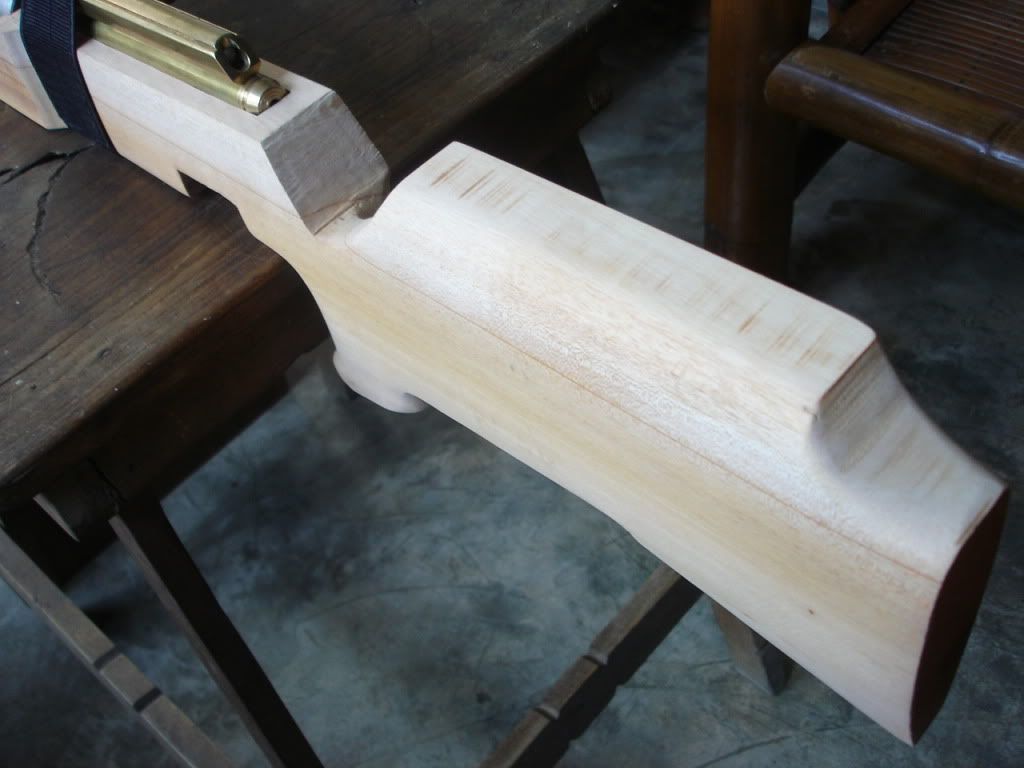

July 9, 2009After chunks of wood roughly shaped, here's one of the stocks. First stock finished fit tested, this one is batmon's work after a few days of cutting, filing and sheets of sandpaper. Right side   Left side  Top view   A closer view, the inletting and coving for the action was outsourced as this particular stock has a 1.5" OD reservoir. They did a very good job on this one.  The buttstock  The action fitted on the stock  A closer angle, don't mind the black strap its just there for security purpose hehehe.  Very nice fit

|

|

|

|

Post by snyper on Aug 26, 2009 6:54:23 GMT 8

August 7, 2009Finally the first prototype is now completed. we are at the range to test and see how it performs at longer ranges. We initially used C02 for this break in test to see if there are any leaks, highest FPS achieved was 680 and highest fill pressure was at 900psi. We already run about 70 shots though and grew tired. At least we are satisfied that it holds air. Was not able to take a pic of he shot group, but at 55 yards about 50 shots of the 70 formed a hole of about the size of a 5-peso coin. Gun already set in the stock  Closer look, guage installed  Closer look at the guage   Top View  Rear view    Barrel Protector, this does not touch the barrel you can actually insert a dental floss through it.    Batmon, testing the gun   Don't mind the gun on the foreground thats my good old armscor on its new stock. Both the woodstock are undergoing an oil finish process. Still a work in progress.

|

|

|

|

Post by snyper on Aug 26, 2009 6:55:26 GMT 8

August 8, 2009After initial testing of the CO2 on the gun, the next day we rented a scuba tank to test the gun on compressed air. Our goal is to use a starting pressure of 1800psi. But for this test we used 2000psi. Batmon also changed to a stiffer spring anticipating that we will be using higher pressure. I was not able to come early with the camera so they did the test anyway to their surprise the chrono read 1038fps!. Way too much power. Here's what I was able to record when I arrived,  Still too much power for our planned design. A few runs on the lathe and some tweaks retesting began. Blow are some pics, we did not want to go to the range, just contended with about 20 yards at Mang pepe's place. Batmon on the bench, to our exitement I forgot to take pics of the first shot. This one is around the 24th shot already  Here we paused so that Mang Pepe can check the backstop, we need better backstops now! hahaha.  Around the 40th shots the FPS has already gone down to C02 levels, we just kept going on to see till what pressure we can keep on shooting.  The grouping after 55 shots  In summary: In summary:Starting Fill: 2000psi reservoir cap: 325cc Highest FPS: 994.3 FPS(using 19 grains SZ) Lowest FPS: 418 FPS Ending Fill: 150 psi (more or less) Total shots fired: 55 shots. I'll edit this post for the actual shot strings. For now since this is not yet the ideal FPS we are aiming for. Additional tweaks will be done but the goal today is achieved and data was gathered. This needs a round of coffee on the round table. hahaha! STARTING FILL: 2000psi

Shot Velocity

No. FPS

1 991.4

2 994.3

3 987.9

4 987.5

5 988.2

6 987.0

7 980.3

8 977.7

9 973.7

10 969.0

Shot Velocity

No. FPS

11 964.2

12 960.0

13 954.2

14 948.0

15 941.8

16 936.4

17 929.0

18 923.8

19 917.7

20 910.0

Shot Velocity

No. FPS

21 907.5

22 900.7

23 891.9

24 887.7

25 879.7

26 869.9

27 863.0

28 853.0

29 846.5

30 835.2

Shot Velocity

No. FPS

31 830.1

32 815.5

33 805.8

34 794.0

35 782.8

36 770.8

37 756.7

38 746.0

39 731.4

40 711.3

ENDING FILL: 600psi NOTE: I did not include the velocities from shot 41-55 as it is already in the CO2 range.

|

|

|

|

Post by snyper on Aug 26, 2009 7:41:05 GMT 8

After more tweaks the gun is now showing better consistency (more than 1000 rounds shot already) we want to see how the gun will do in actual competitions. The Gun in action during the recent Kadayawan '09 fun shoot. Here's Batmon, testing our custom benchrest PCP (Serial #001), though it still needs a lot of work, it already rocks.  Raymond, shooting at the turkeys   Here's some data we gathered after doing some tweaking.: New shot string info after some modifications: Super Zero(out of the box) cal. 22

Starting pressure: 1950psi

Ending pressure: 1000psi

Shot # FPS(SZ)

1 836.0

2 825.9

3 817.9

4 819.8

5 819.9

6 821.3

7 809.3

8 825.2

9 812.9

10 808.6

11 821.1

12 819.6

13 830.4

14 855.7

15 823.1

16 826.5

17 846.5

18 831.1

19 832.9

20 811.1

21 830.0

22 836.0

23 823.4

24 836.0

25 840.5

26 855.8

27 821.8

28 846.2

29 814.4

30 821.6

31 833.1

32 825.8

33 824.4

34 827.4

35 838.4

36 833.3

37 834.9

38 848.6

39 834.1

40 814.2

41 811.5

42 815.3

43 810.2

44 816.2

45 828.8

46 825.2

47 820.6

48 816.2

49 836.4

50 802.5

51 802.0

52 806.2

53 814.6

54 813.1

55 783.1

56 801.9

57 784.0

58 793.2

59 768.8

60 781.0

Silver Streak (out of the box) cal. 22

Starting pressure: 1900psi

Ending pressure: 700psi

Shot # FPS(SS)

1 818.2

2 816.1

3 829.1

4 814.3

5 813.1

6 838.5

7 818.4

8 824.7

9 826.7

10 833.2

11 827.6

12 828.7

13 830.4

14 837.7

15 856.4

16 835.2

17 840.0

18 844.8

19 851.5

20 851.2

21 842.3

22 834.7

23 841.9

24 844.2

25 834.7

26 844.4

27 860.6

28 849.4

29 846.2

30 841.7

31 824.1

32 830.5

33 843.3

34 865.8

35 838.7

36 829.6

37 838.0

38 824.0

39 823.1

40 820.1

41 830.3

42 816.7

43 812.3

44 810.2

45 815.2

46 806.7

47 806.5

48 797.4

49 800.4

50 773.4

51 769.1

52 768.5

53 759.2

54 761.6

55 753.5

56 731.0

57 725.0

58 704.8

59 736.5

60 711.3 |

|

|

|

Post by neilaxe on Aug 26, 2009 12:51:04 GMT 8

hello sir snype. oretxua here. really nice sir. inspiring jud kaayo. pila tanan ang gasto aning project nimo sir?

|

|

|

|

Post by snyper on Aug 27, 2009 19:07:17 GMT 8

@ nielaxe, bisaya pud diay ka?! hehehe taga asa man ka? Wla pa jud namo na kwenta ang gasto kay as the project progressed namalit pud mi ug mga tools para madali among fabrication. Hopefully kaning next two guns nga nearing completion we will be able to give a cost estimate.

|

|

|

|

Post by quickshot on Aug 28, 2009 9:38:14 GMT 8

bro snyper saan tayo makabili ng pressure gauge na maliit dito sa dvo at magkano?

|

|

|

|

Post by snyper on Aug 28, 2009 19:42:13 GMT 8

quickshot, Ino-order ko from US. May parating ako limited stocks lang.

|

|

|

|

Post by neilaxe on Aug 28, 2009 23:39:18 GMT 8

sir snyper, taga Bohol jud ko sir. pero moari ko og cebu from time to time.. nindot jud inyo project sir dah. my dad is planning to convert his trusted CORAZBAL Co2 into pcp. wala pang jud mi kabalo sa type of metal sir. do you happen to know? nag.inquire nko sa cebu about T6 alum TUBE. wala man gud.. please some input sir if you have something to share. thanx!! more power!!  |

|

|

|

Post by sniper72 on Aug 30, 2009 8:02:06 GMT 8

Sir snyper if ever maglaunch namo sa inyo PCP or mafinal na ninyo ang total cost sa PCP,paki PM me naman sa price para magtigom ko daan..I hope magfabricate na pod mo para sa hand pump aron complete package na dayon ang pricing..Sir makaconvert ba japun mog Armscor CO2 to PCP para sa mga low budget like me..hehehe...

|

|

|

|

Post by snyper on Aug 30, 2009 9:44:07 GMT 8

sir snyper, taga Bohol jud ko sir. pero moari ko og cebu from time to time.. nindot jud inyo project sir dah. my dad is planning to convert his trusted CORAZBAL Co2 into pcp. wala pang jud mi kabalo sa type of metal sir. do you happen to know? nag.inquire nko sa cebu about T6 alum TUBE. wala man gud.. please some input sir if you have something to share. thanx!! more power!!  Bro, di kaayo ko familiar sa CORAZBAL nga CO2 AG, murag wa pa ko ka kita ana ngari sa DVO (nindut cguro ma share nimo pix) or wla lang ko kabantay. As for the conversion we need to take a look at the internals of the gun kung pede ba sya ma convert to PCP. If you have a trusty airgunsmith he would be able to give you an idea. We can send you raw materials like the T6 tubing, though its on an order basis cause it is very expensive to stock it. |

|

|

|

Post by snyper on Aug 30, 2009 9:52:16 GMT 8

Sir snyper if ever maglaunch namo sa inyo PCP or mafinal na ninyo ang total cost sa PCP,paki PM me naman sa price para magtigom ko daan. No problem bro, actually na gani naka linya, hehehe. Puro mga kaila kasagaran kay kaila man sila sa among partner gunsmith. He has a track record of making durable and collectible Co2 AG (Pepes Guns). We will definitely let you know once we finalized everything. I hope magfabricate na pod mo para sa hand pump aron complete package na dayon ang pricing..Sir makaconvert ba japun mog Armscor CO2 to PCP para sa mga low budget like me..hehehe... Actually its in the plans, pero sama sa panultihon "one step at a time" Amo pud i share ngari sa forum ang mga updates sa among projects aron ma bibo pud ang airgunning scene natong mga bisaya hahaha. |

|

|

|

Post by neilaxe on Aug 30, 2009 23:10:38 GMT 8

this is the Corazbal sir.    it has a push-kock mech-. patterned from an old benjamin air rifle. we want to convert it to pcp to increase its power and range. nway, thank you for the input sir Snyper. actually, all we need is the material. mY father can take care of the rest. as for the fabrication if ever there is, he usually just make use of local machine shops here and just instruct the machinsit what to do . he'v done it many times. (although not yet in pcp: first time he learned about pcp) (co2 lng, say change tank or whatsoever. he fixes airguns in our area. the only lacking is the machine so he can be a gunsmith. hehehe anyway, how much will it cost us if my father will decide to order the T6 from you sir? the original plan was to use a smaller metal like the one in Benjamin Disco. BUT WE dont know the type of metal. we dont even know if available ba ang type of metal sa cebu, i inquired once sa cebu in one of the major metal distributor about what metal tube can sustain 3000 psi, i didnt have a good answer. wasnt able to buy (weird for a major metal distributor) or maybe wala me nagkasinabot sako kaistorya. ahahhah!! nway, please keep us posted on your project sir. kinda excited to see your pcp pump. who knows, we will order from you in the future instead of converting ours. regards, Neilaxe |

|

|

|

Post by snyper on Aug 30, 2009 23:58:35 GMT 8

neilaxe, thanks for sharing from your description the kocking mechanism is similar to a crossman 160 if I am not mistaken. As for your planned DIY for a pcp conversion using your existing Co2 AG, yes we can supply you with the T6 tube. currently we have 1.25" OD T6 tube. Let me know what length you need. Just one thing that you will need to keep in mind is the safety factor. As you may already know PCP's have higher working pressure (Co2 is somewhere in the 900psi) as most pcp's are at 3000psi. You will have to decide the working pressure you will be using for the AG then make sure reinforcement on the existing AG is done. Honestly we have not done that so I cannot give you any more advice on the conversion. Good luck and play safe! best

|

|

|

|

Post by neilaxe on Aug 31, 2009 18:34:01 GMT 8

cge sir, ill tell my dad about the T6. if he'll go for it, I'll PM you then.. nO worries about the Safety. we always keep that in mind. thank you sir snyper! More Power!  |

|

|

|

Post by snyper on Aug 31, 2009 18:57:07 GMT 8

your most welcome bro! just pm me for any updates

|

|

|

|

Post by neilaxe on Sept 9, 2009 15:12:02 GMT 8

sir Snyper, YGPM..

|

|

|

|

Post by ariscanete on Dec 22, 2009 20:25:54 GMT 8

snyper, when will you finalize the design of this low-cost PCP rifle? as a matter of fact, si Kingjim is looking for a PCP rifle here in manila and even met him in Megamall a couple of weeks ago at Hahn Store.....I think he is a member of Davao Airgunners group too. Maayo unta ako ang unang Bisdak diri sa Manila/Laguna nga maka-introduce anang inyong PCP rifle to my colleagues in LAGSA..Laguna Airgun Shooters Association. Pero i guess you need to wait till gunban is lifted on June 9... Kung gusto ninyo, you can bring your PCP rifles on our Firing Range in Cabuyao which is held every 1st sunday of the month. Di ko kahibalo when will be the Open Invitational Shooting Competition sa amoa diri sa LAGSA coz last time was November 8. All known Airgun makers like Lacanlale of JBC and Mang Mario of Muli/Nimrod airguns are there too...at least you can compete side by side with them sab.... Our events or category for competitons are BR70 MS, BR25, MS Scope Rifle Category too...Firing Range is Outdoor, medyo windy ng konti and sometimes very dusty. But your guns can be put to the TEST against some of the BEST...

|

|

|

|

Post by batmon on Dec 22, 2009 22:21:47 GMT 8

ariscanetewelcome sa forum bro bisdak pud diay ka hehehehe. that would be great bro competing side by side with other local brand aron makita ang katag hahaha. we have almost similar events bro see WAGS board naa didto mga comp na amo gi stage.

|

|

|

|

Post by ariscanete on Dec 23, 2009 4:14:35 GMT 8

batmonbai Bisdak kaayo ni oi....tan-awa n lang akong apilyedo - sugbuanon kaayo. maayo that ur open to such an idea of competing side-by-side with known competitors. Hope you get a crack of a big market here in Metro Manila. It will be my 1st time to see such an event coz last time FilArms (i think) has no team there last nov.8 except for some Airgunners who happens to use FilArms. Also there are no Armscor PCP rifles there during the competitions. JBC and Muli fielded their teams too... Cge bai daghan salamat....lets keep in touch...

|

|

|

|

Post by snyper on Dec 29, 2009 23:43:53 GMT 8

snyper, when will you finalize the design of this low-cost PCP rifle? as a matter of fact, si Kingjim is looking for a PCP rifle here in manila and even met him in Megamall a couple of weeks ago at Hahn Store.....I think he is a member of Davao Airgunners group too. Maayo unta ako ang unang Bisdak diri sa Manila/Laguna nga maka-introduce anang inyong PCP rifle to my colleagues in LAGSA..Laguna Airgun Shooters Association. Pero i guess you need to wait till gunban is lifted on June 9... Kung gusto ninyo, you can bring your PCP rifles on our Firing Range in Cabuyao which is held every 1st sunday of the month. Di ko kahibalo when will be the Open Invitational Shooting Competition sa amoa diri sa LAGSA coz last time was November 8. All known Airgun makers like Lacanlale of JBC and Mang Mario of Muli/Nimrod airguns are there too...at least you can compete side by side with them sab.... Our events or category for competitons are BR70 MS, BR25, MS Scope Rifle Category too...Firing Range is Outdoor, medyo windy ng konti and sometimes very dusty. But your guns can be put to the TEST against some of the BEST... Na meet na nako si kingjim bro, in fact I bought him to mang pepe kay aron ma paayos nya iyang filarms. As for competitions, duna pud mi mga padula if you look around the forum and we also compete with other airgun makers. Ang wla pa lang mupakita diri ang JBC, though I know that there are JBC owners here in Davao. Siguro if we have more competitions and they learn about it we will have more AG's to see. Kung wla mi nag pursue sa PCP design dli pa tingali katilaw nang mga local ug homegrown PCP, unless mupalit sila sa Manila. Di pud namo masulti nga low-cost ang among design because it uses brass and T6 Aluminum. In effect mas mahal pa gani kaysa kay muli kay bakal ra man. We want one that would look different and will have less maintenance. Anyway, we hope for the best in the year 2010 ! Cheers! |

|